Procurement for Housing and Building Better share what we’ve learnt, how it’s informed our decisions and the ambition for our second procurement route for housing associations and local authorities.

One of the central goals of Building Better is to share learning. In the past, many housing associations and local authorities procured MMC in isolation which meant there was no build-up of knowledge, no repository of what worked and what didn’t – and mistakes happened over and over.

To mainstream MMC in social housing we knew this cycle had to be broken. Collaborative understanding was, and still very much is, at the heart of our first procurement solution for factory-built homes – a category 1 framework launched in 2021.

Through this agreement, Building Better members work with a selection of trusted manufacturers; listening, learning and innovating together. This is all about developing our awareness of what best practice looks like, pooling hard data and field knowledge, and it’s working – since July 2021, our members have put dozens of schemes forward, getting costs on over 900 MMC homes.

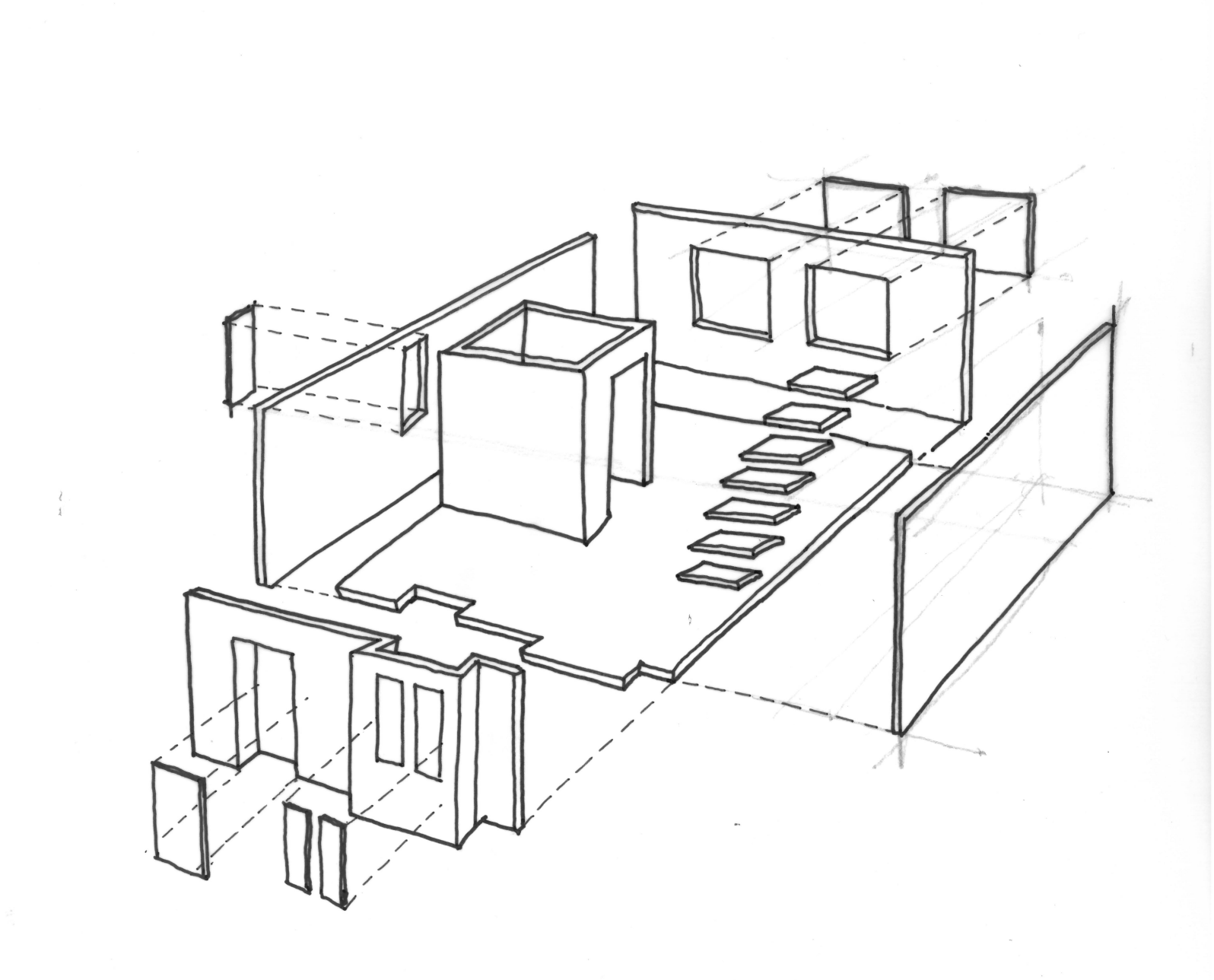

We were keen to replicate this approach for category 2. The ambition was to offer members a similarly user-friendly solution but one that allowed them to buy 2D systems for sites with access issues or where there was a need for increased adaptability.

But the panelised housing marketplace is very different from volumetric and as we engaged with manufacturers and industry experts we began to realise to what extent.

This segment of offsite is evolving rapidly; products and methods are continually being adapted and new entrants regularly appear.

A wide variety of solutions and systems exist, and they vary vastly in both materials used and the level of completeness that comes with individual products.

There are many differences within 2D categories: standard timber, cross laminated timber (CLT), steel, structural insulated panels and hybrid systems. And not all suppliers conform to a frame construction that fits neatly within those categories.

Manufacturers, too, vary in size, capacity and experience. Many have delivered panelised systems for hospitals, schools and offices but only a few have large scale experience in residential.

The emerging nature of this market means that social housing organisations have, to date, been wary of category 2. When we asked providers about the barriers to using 2D, some said they were anxious about committing to a manufacturer; not knowing if that company or even this form of MMC would be around in four years.

We knew a different procurement approach was needed; one that would still provide technical excellence and ease of access like our category 1 framework, but a solution that didn’t ‘clip the wings’ of manufacturers operating in such a fluid environment.

A fixed framework, where suppliers can only join within a limited window and are locked in for years would not offer the flexibility housing organisations need to get the best from this market.

That’s why we have designed an MMC Category 2 Dynamic Purchasing System (DPS) that will launch in May 2022. Offering two lots – full turnkey or supply/install only – it will provide a compliant route to market for Building Better members whilst retaining the adaptability needed to welcome new, innovative solutions and suppliers.

Suppliers can find us at any point over the next four years and this will give housing organisations greater access – they can choose from an extensive range of options around design, layout, specification, and geography but within a structure that provides confidence and security.

Any manufacturer wanting to apply must first be certified by the Buildoffsite Property Assurance Scheme (BOPAS) or assessed and accepted by building warranty provider the National House Building Council (NHBC) and their products must meet the Future Homes Standard. To be accepted onto the DPS, manufacturers then have to go through a stringent selection procedure that looks at their commercial, social and sustainability credentials.

There are some compromises with this approach. One of our core objectives with Building Better was removing procurement red tape. Our category 1 framework does this, enabling price certainty and direct award so development teams can engage early without the need for further competition.

However, with a DPS, individual sites still need to be competitively tendered via a mini-competition with pricing determined project-by-project. Although this is not ideal, it is reflective of where the panelised market is. Manufacturers generally don’t offer standard house types and usually they design bespoke solutions to meet the needs of each client and site – so direct award wouldn’t be appropriate.

And it’s this customisation potential that is the real strength of category 2 systems. They have the ability to be manufactured to a client’s own individual designs and house types and they can help to provide solutions to those sites that might already have planning, without going back to the drawing board.

In terms of the mini-competition process, we have developed a number of streamlining measures. Firstly, each member will receive a suite of tender template documents and we’ll support them to pull together a tender information pack for manufacturers.

Secondly, we’ve developed a ‘decision tree’ of guidance that asks key questions about a housing provider’s requirements and then walks them through their options, filtering this diverse marketplace and minimising the number of bidders involved in each mini-competition.

Ultimately, a major benefit of this DPS approach is the learning. As an alliance, we’ll be able to grow our understanding of what housing organisations actually require with cat 2 and the technical solutions they gravitate to.

Creating a framework now would have meant guessing the answers. But a DPS allows us to gather data and feedback on products and manufacturers, educating ourselves. And this will help us achieve our longer-term vision – to appoint a small number of manufacturers to a carefully designed, well-informed category 2 procurement solution in the not-too-distant future.

This DPS is an important part of our offsite journey. Giving social housing providers access to approved manufacturers and a streamlined call-off process helps us to normalise offsite and use it at scale across the sector. We hope you join us on that journey

Written by Trina Chakravarti, Project Director, Building Better and John Bellamy, Category Manager for Construction & Sustainability, Procurement for Housing (PfH)

20 April 2022